Aluminium Profile Extrusion Production

With over 70 years of experience, Çuhadaroğlu operates as an integrated company in Istanbul, within a 90,000 m² production area that includes an aluminum profile casting line, extrusion lines, a die shop, surface treatment facilities, mechanical processing, and assembly lines.

Çuhadaroğlu manufactures all its aluminum products from primary aluminum that is globally recognized and certified. Besides, Çuhadaroğlu carries out its aluminium billet and aluminium profile production in accordance with ISO 9001: 2015 and TSE standards. In addition, ISO 14001, ISO 27001 and ISO 45001 are among the certifications that we have complied with.

We are producing primary aluminium billets having a diameter range of 6, 7 and 10 inches with the length 7.20 meters in maximum. Our high-tech brand new controlling equipments allow us to produce high sensibility billets in order to control chemical composition before and after casting. Our plant achieves highest billet casting quality, with using Wagstaff degassing system which is integrated electromagnetic liquid aluminium mixing technology in order to ensure the lowest hydrogen and lowest inclusion ratio in the aluminium structure.

Being aware of the fact that high product quality and high productivity can only be provided, based on an excellent die design. Çuhadaroğlu develops, designs and produces aluminum extrusion molds through its own die shop. Çuhadaroğlu is using state-of-art machinery and equipment that are operated through CAD/CAM (3-Dimensional Design and Operation System) technology, which enables the technical properties of each product to be reproduced. The die designs are transferred to the CNC Mold-Processing Center via computer system. Thanks to the high-precision bench-machines, it is possible to produce aluminum profiles that meet the dimensional tolerances required by customers as well as all the related international standards. Extrusion Çuhadaroğlu has an annual production capacity of 20.000 tons extruded aluminium sections through 1650-Mtons, 1800-Mtons and 4000-Mtons aluminium extrusion presses. Depending on the geometrical shape of the profiles; Çuhadaroğlu can produce aluminium profiles between 0,4 - 65,00 kg/m, with a maximum width of 400 mm. Mainly producing 6000 alloy for construction, automotive, machinery and furniture industries, as well as 5000 alloy for automotive industry. We are realizing our profile manufacturing with 3 extrusion lines: • 1650 Mtons Power / Leistung: Aluminium Billet Diameter 152 mm (entering size) • 1800 Mtons Power / Leistung: Aluminium Billet Diameter 178 mm (entering size) • 4000 Mtons Power / Leistung: Aluminium Billet Diameter 254 mm (entering size)

Çuhadaroğlu mechanical process carry out various operations for regular systems as well as production for various industries as custom based solutions, like

Surface treatments acc to DIN 17611 E0 Degreasing and Deoxidation Mechanical surface blemishes, e.g. Marks and scratsches, remain visible. E2 Brushing Uniform, shiny surface with visible brush marks. E4 Grinding Uniform, shiny surface. E6 Etching Silk matt or matt surface. Çuhadaroğlu surface treatments facility is the only facility in the world that makes hybrid application of both anodic oxidation and powder coating in the same line. As a member of ESTAL (European Association for Surface Treatment on Aluminium), our facility has Qualanod and Qualicoat-Seaside quality certificates which are awarded by AYİD (Aluminum Surface Treatment Association) to Çuhadaroğlu as a first time in Turkey. Since 70 years, our facility is capable of making anodic oxidation coating up to 40 μm thickness in natural and diverse colors while minimum coating thickness for our system profiles is 15 μm.

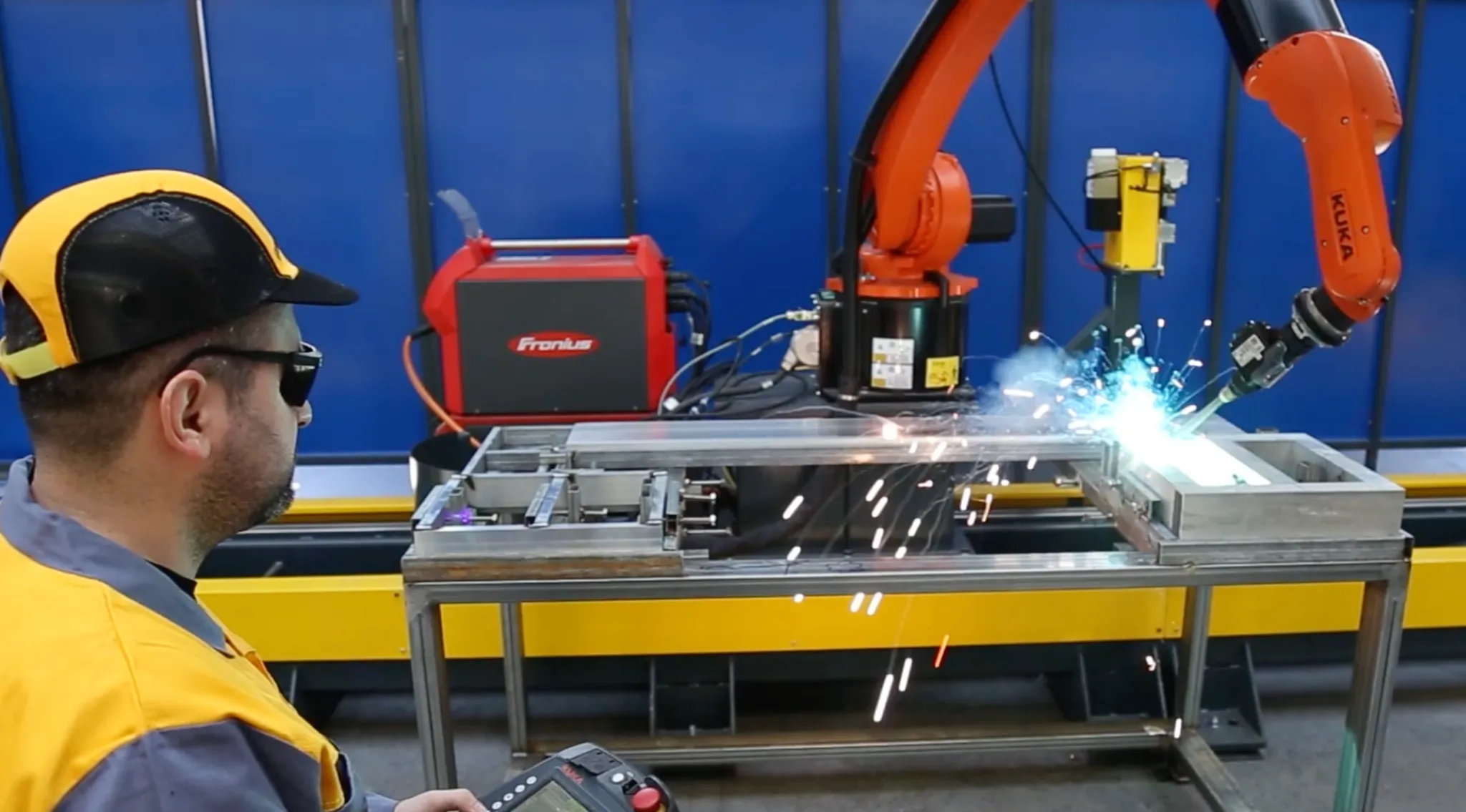

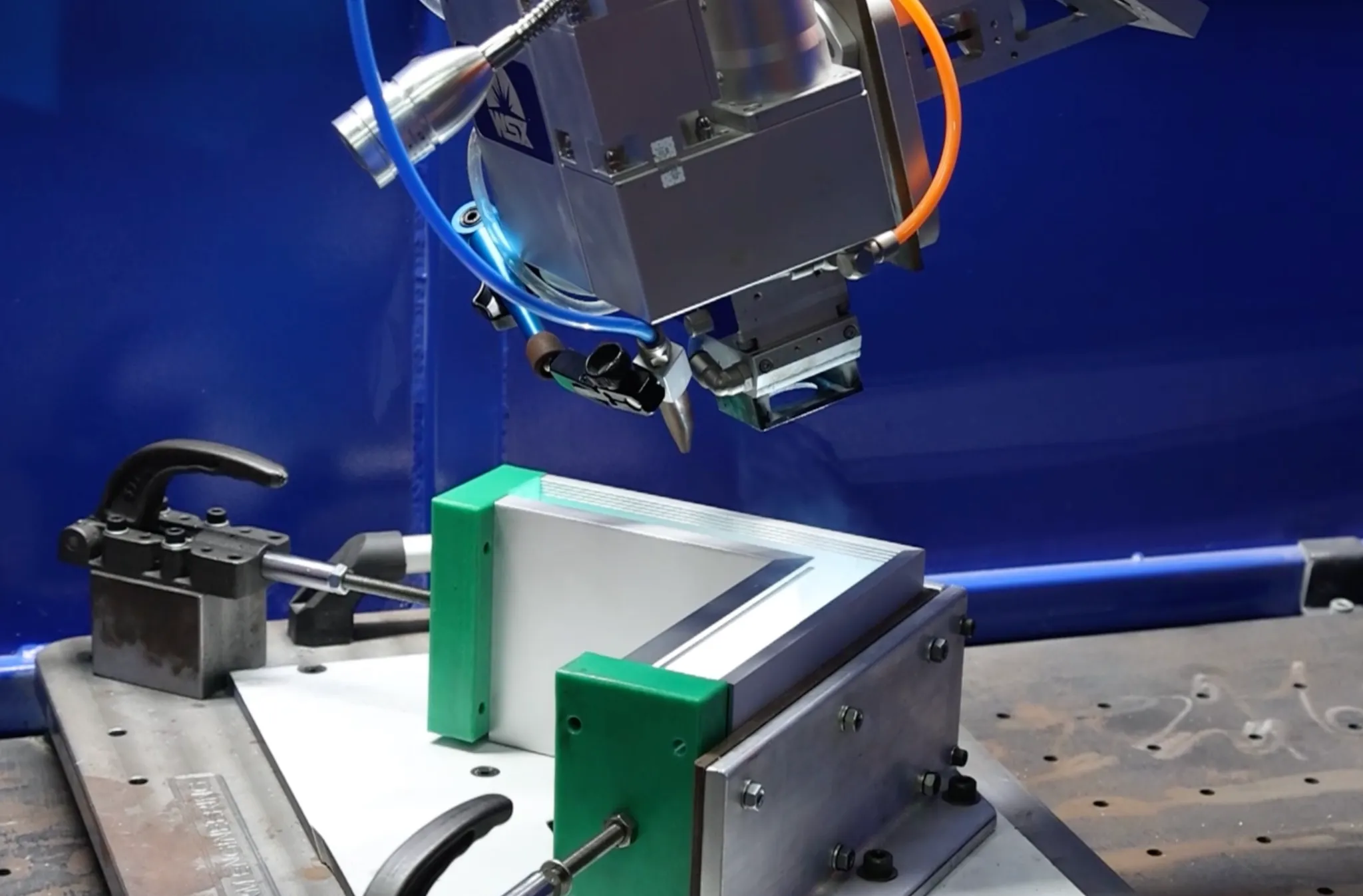

Our facility is equipped with two advanced robotic welding machines. These machines MIG and TIG Robotic Welding Machine Laser Welding Machine Provides exceptional durability and flawless weld quality with advanced laser power and precise focusing capabilities. Project Specific Fixture Design & Production Custom-designed welding fixtures and welding inspection fixtures are developed and manufactured by our technical team for each project. This ensures both quality and process efficiency in your operations.

support MIG, TIG, and Laser Welding applications, offering tailored solutions for diverse project needs.